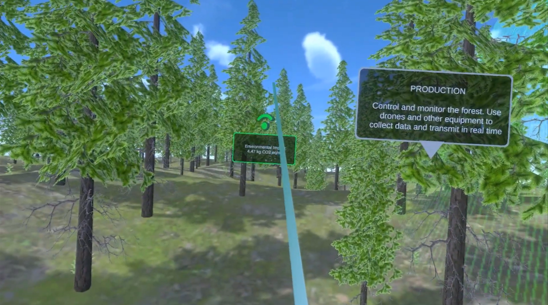

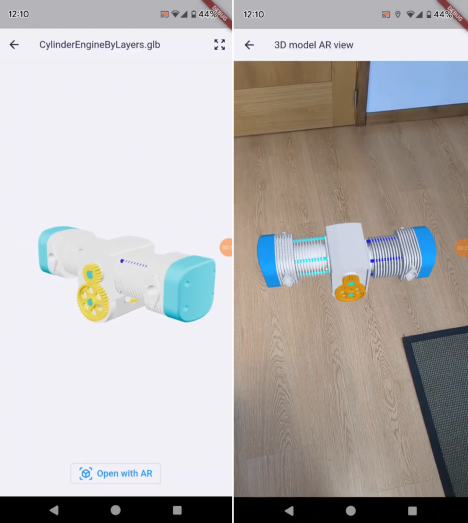

Computer-aided design (CAD) software is used in the product design and development to design complex and detailed prototypes. It provides good assistance and solid data generation to designers and engineers. In order to remain competitive, industry is always seeking for higher process efficiency and product quality enhancement in the shortest period of time. Continuous research keeps going to make it possible. Virtual reality has been one of the research focus in the recent years. It is studied and applied to be used as an assistant tool in the product lifecyle management, particularly in facilitating the development phase. However, the implementation process from CAD to virtual reality remains a challenge due to time consumption and technology complexibility. In this work a real-time virtual reality harvester simulator was developed. The start point was a 3D harvester CAD model. It was used the CAD simulator AGX Momentum, a game engine Unity and the physics engine AGX Dynamics to create dynamics simulation, to design a virtual forest environment and to enable physical controllers interact with the model. With the capabilities of AGX Momentum, it was added dynamics motion directly in the CAD software, creating fast CAD simulations. A virtual scene was designed with Unity to simulate an environment and the immersion of the user on it with Oculus Rift device. The harvester model was imported to the Unity scene with AGX Dynamics. In the end it was obtained a real size virtual prototype, with the possibility of interacting and control it using physical controllers. The user can visualise the scene in real-time through a head mounted display, providing him the experience of a real machine operator. Driving the harvester in a simulated forest, allowed to test the model in a hypothetical real scenario. The process of implementing the CAD model in virtual reality used in this work, revealed to be efficient and intuitive. However, because it is a complex and large model, it was necessary to remove certain bodies (without dynamics effect) and reduce the number of contact points between components in order to balance the speed and performance of the simulator. Following the same method used in this work, Other CAD models can be imported to virtual reality and be dynamically simulated.