VR Digital Twin of a logistics serviceVR app

Using VR to demonstrate how a logistics service works. Show the value of the service to potential companies.

Read More

Published on Jun 15, 2017 by João

This project was completed in the course Technology Of Joining Processes at Univesity of Aveiro. It consisted of design and manufacture a stand for students festival.

The client is the Mechanical Engineering Student Organization (NEEMec), that actively organizes many academic and pedagogic events for students. Two times a year, NEEMec is present in the student festivals in Aveiro, where more than 15 000 students participate to celebrate the start and the end of their academic lives.

In these events, organizations can participate either by leasing stands to the main organizer or utilize their own stands. In order to reduce the costs on participation, NEEMec asked our team to build a stand that could be used in the events for many years.

With the availability of many different machineries from the Mechanical Engineering Department, we immediately started the idealization process.

Our team identified at the beginning the project requirements:

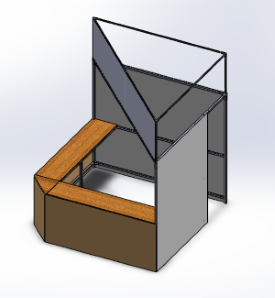

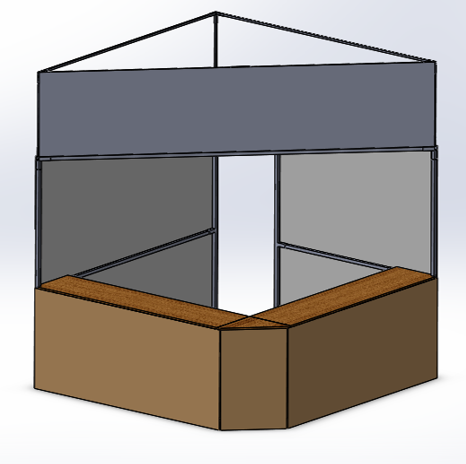

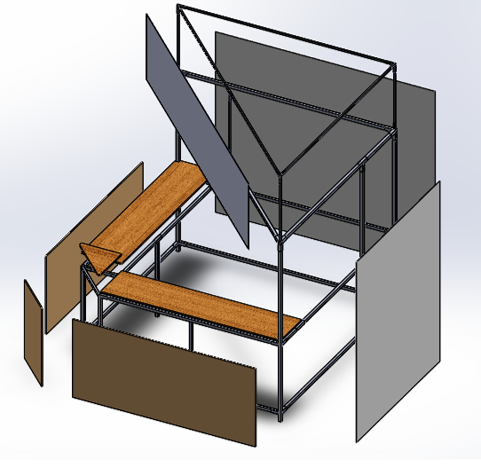

Based on the identified requirements, our team designed several prototypes through CAD software. The design chosen can be viewed in the following images (stand assembled, exploded view and only tube structure exploded view).

This prototype relied on cubic steel profile tubes to give the entire structure stabilization and wooden boards to provide the remaining framework and the bench. Screws and designed connection pieces allows the connection between all parts.

We simulated the design with stress tests in order to guarantee security and stabilization.

After achieving satisfactory results, we bought the necessary material and started manufacturing the stand. We used the automatic saw to cute the tubes (left image) and the MIG MAG welding machine to weld the necessary parts (centre image). On the right image, you can see some members of the team and the first assembly test to the stand.

After all machinery processes were done, all parts were transported to the festival site, assembled and outside decorated. The next photos show the last touches.

The final results of the stand decorated can be seen in the next photo. This was the first time that NEEMec used the stand in 2017. Since then, the same stand has been used in all festivals that NEEMec participates.

We are glad about the results. We considered this project really interesting since our team successfully meet all requirements, even though the short deadline (less than 3 months since the start of the course). Also, we were able to be involved in all stages of product development and manufacturing of the project, expanding our experience and knowledge in Mechanical Design and Project Management.

Project team members:

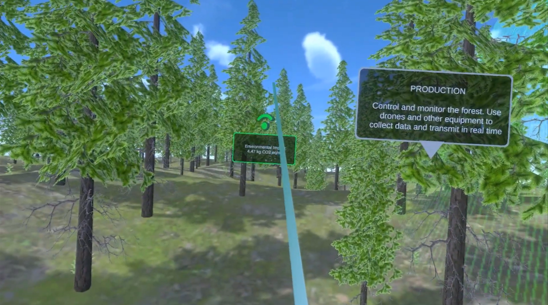

Using VR to demonstrate how a logistics service works. Show the value of the service to potential companies.

Read More

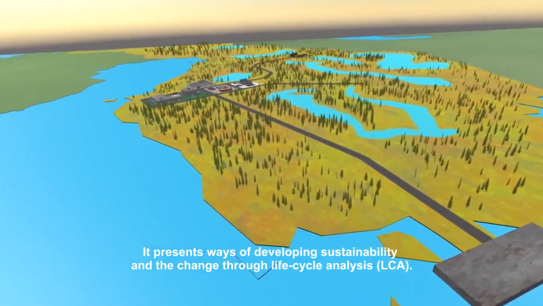

Forest ecosystem in the future with VR. Demonstrating futuristic value chain.

Read More

VR demo about future metal ecosystem. Demonstrate futuristic value chain.

Read More